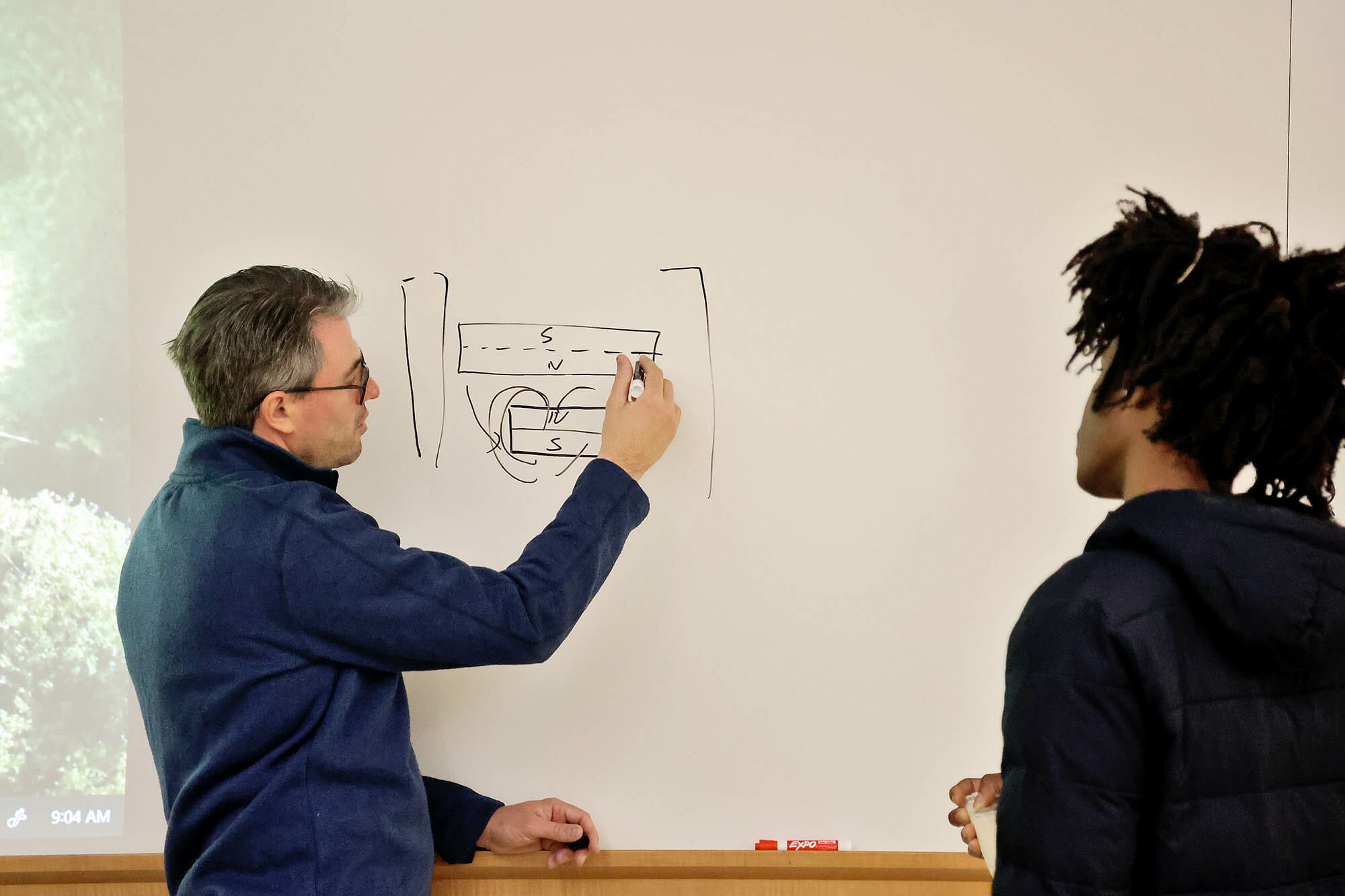

Paul Zahller’s Upper School physics students are learning all about the power of magnets and their ability to revolutionize transportation through a series of experiments with maglev technology. They have been busy building their own maglev trains!

Maglev, which is shorthand for « magnetic levitation, » is a system of train transportation that uses two sets of electromagnets: one set to repel and push the train up off the track, and another set to move the elevated train ahead, taking advantage of the lack of friction. Such trains rise approximately 10 centimeters (3.9 in) off the track. Maglev is smoother and quieter than traditional, wheeled transportation thanks to the elimination of much of the physical contact between wheels and track.

Since maglev requires a guiding rail, it is mostly used in railed transport systems like trains. Many systems use magnetic attraction pulling upwards against gravity for these kinds of systems as this gives some inherent lateral stability, but some use a combination of magnetic attraction and magnetic repulsion to push upwards. Magnetic levitation technology is important because it reduces energy consumption, avoids wear, and has very low maintenance requirements.

Although maglevs eliminate a key source of friction—that of train wheels on the rails—they must still overcome air resistance. This lack of friction means that they can reach higher speeds than conventional trains. At present, maglev technology has produced trains that can travel in excess of 500 km (310 miles) per hour.

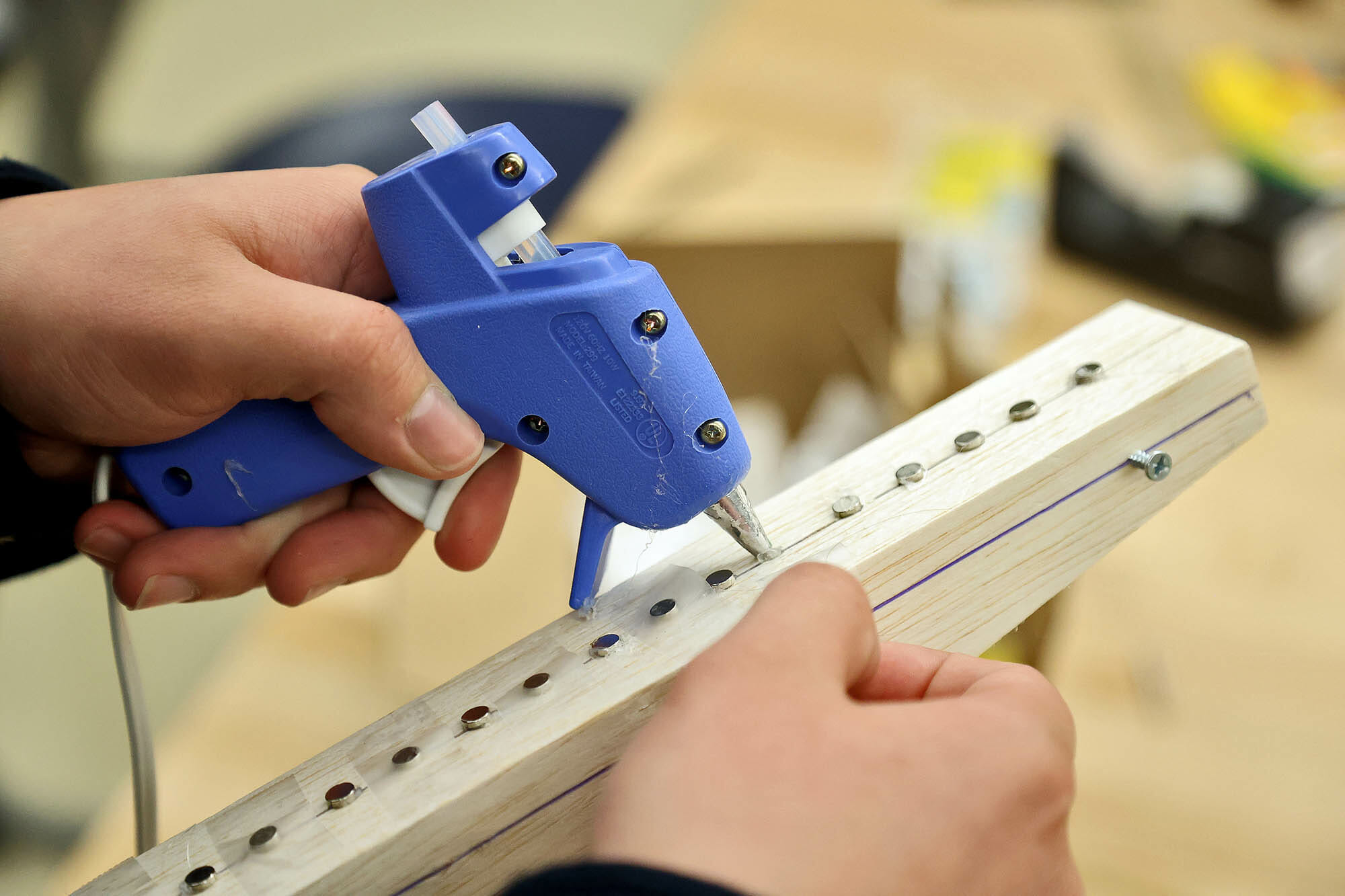

Zahller’s students learn to achieve levitation by manipulating the placement of magnets on their wooden « trains. » They are using neodymium magnets, which are made of neodymium alloys. These magnets are widely used in products like microphones, professional loudspeakers, in-ear headphones, high-performance hobby DC electric motors, and computer hard disks, where low magnet mass (or volume) or strong magnetic fields are required. Larger neodymium magnets are used in electric motors with a high power-to-weight ratio (e.g., in hybrid cars) and generators (e.g., aircraft and wind turbine electric generators).

The students are constructing their own wooden module « maglev trains, » adhering to a strict set of requirements. Their modules must levitate exclusively with magnets, and levitation should be maintained for three seconds. Modules cannot be helped by outside supports and can’t touch down, and were tested using trials on a cardboard platform. The designs must include 75 or fewer neodymium mini magnets and four or fewer neodymium bar magnets.

Perhaps in the future, one of these student scientists will develop maglev train systems for widespread use!