Throughout the semester, Upper School Science 10 students have been answering some burning questions that recently led to their flagship fire extinguisher projects. In scientific terms, they’ve been diving into stoichiometry, the branch of chemistry that studies the relationships of, often quantitatively, combining elements. They’ve been looking at volume, pressure, acid-base chemical reactions, and the effect nozzle shape has on the distance water can be shot.

Based on a curriculum strategically developed by the science teaching team just a few years ago, students are going far beyond memorizing facts and procedures for this course. Instead, they are being challenged to collaborate, engage in discourse, utilize driving questions, and use the “knowledge-in-use” perspective where they learn by applying knowledge to make decisions and solve problems while also evaluating when and how to get more information when necessary. Upper School Science Teacher Rachel Tourais explained the goal of the project this way: “My hope from this project is that students would creatively and methodically problem-solve designing a solution to a simple problem.” The fire extinguisher project exposes students to real-life experiences in the worlds of science and engineering in order to help them more deeply connect authentically with the material in realistic ways.

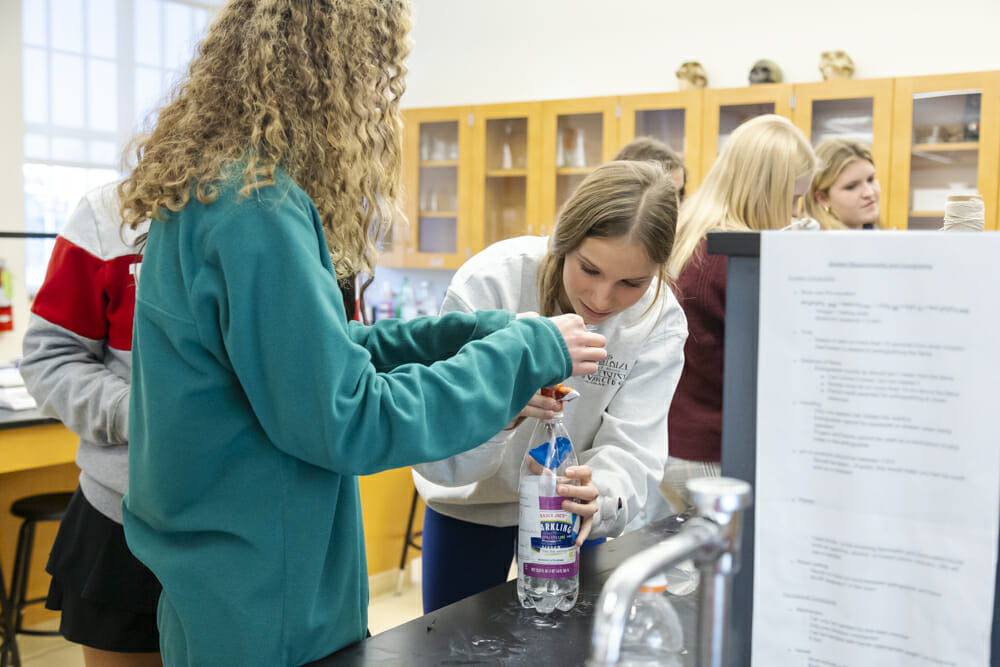

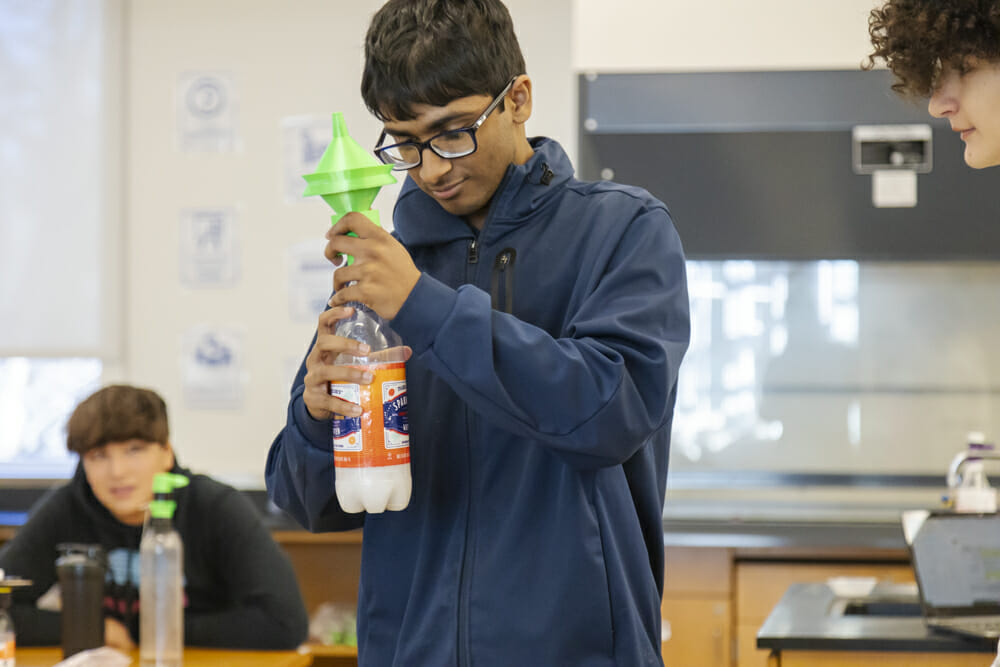

To get learning firing on all cylinders in and around the classroom, students participated in a sequence of experiments, labs, and lessons throughout the semester, all of which came together when they designed, created, and ultimately performed final tests of their very own fire extinguishers. One new lab offered this year allowed students to test water hoses and nozzles of different sizes to examine how the size of a nozzle’s opening affects the distance water can be shot from a garden hose. Ethan Graf, Upper School Science Teacher, said, “We hoped this lab helped students better understand how to design their fire extinguisher nozzles to shoot carbon dioxide.” The labs worked as “knowledge-in-use” opportunities which “gave students the foundational knowledge to apply to the requirements of the fire extinguisher design,” Ms. Tourais said. “From the Nozzle Lab, students could observe and test the effect of nozzle orifice size on water distance flow, thereby relating volume and pressure. This background gave students a useful starting point in their nozzle design for effectively expelling the evolved gas in their chemical system.”

Other labs completed were:

- The Acid-Base Lab: Students examined the properties of the reactants used in the acid-base chemical reaction that would occur within their fire extinguishers.

- The Corkomodules Lab: Like last year, students propelled their corkomodules across water using carbon dioxide produced by an acid-base chemical reaction.

- A Boyle’s Law Lab: Students investigated the relationship between the volume and pressure of a confined gas.

When it came time to work on their fire extinguishers, the student scientists were divided into small teams of two to three. Next, they underwent formal Tinkercad software training so they were ready to use the system to help create their designs, and they used OneNote Team notebooks to log their ideas.

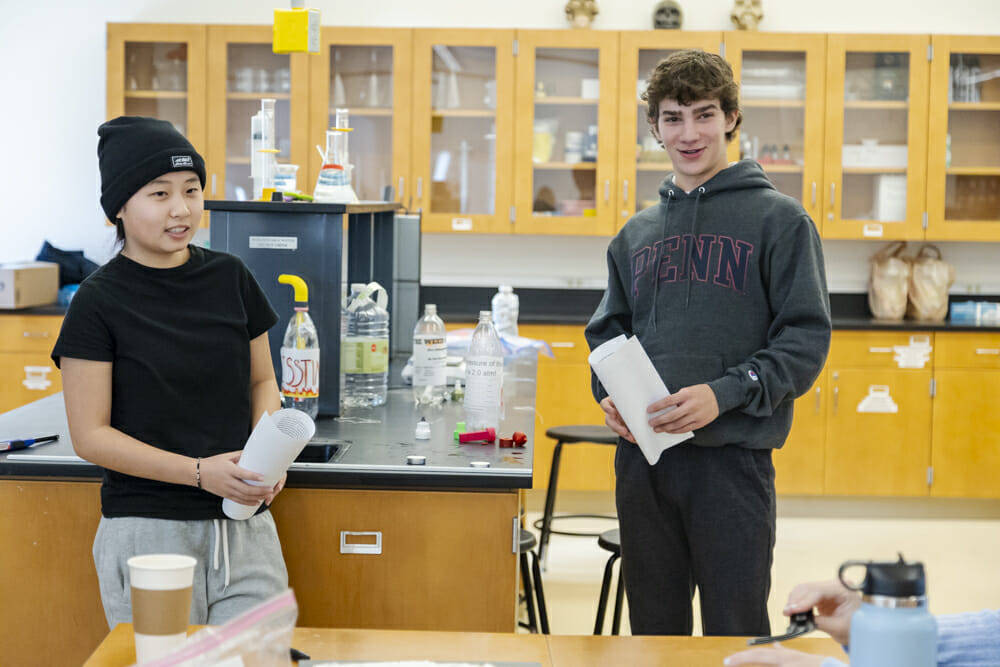

During class, students shared ideas and thoughts before reporting their findings back to their teams. These findings helped lead to possible modification and redesign. Over several subsequent class periods, they continued designing, testing, then redesigning, and testing again with inexpensive materials. Sharing with and learning from peers was a special part of the project for Austin Minges ’25. “My partner and I asked questions with other teams in order to see how to create the best fire extinguisher. This was my favorite part of the project due to the fact that I love socializing and bouncing ideas off of other groups,” he said. “This lab reassured me that I am around so many scholastically gifted high school students. Working together in order to create and come up with a really useful fire extinguisher was the best part about the lab.”

Students loved being able to dream up their designs. Mia Sondrol ’25 said, “I liked how we had freedom over our design and how we wanted it to be created. We were able to create our own ideas for the initiation mechanism and could create that in any way we wanted.” Emily Leyland ’25 commented on all that students had to work with. “I was surprised with how many materials we had available to us,” she said. “My group spent a lot of time in the makerspace as we worked on our prototype to make it fit on the bottle and work, and not only did we receive a lot of support from Upper School Science Teacher Ms. Stephanie Matteson, but from Maker and Robotics Coordinator Mr. Brian Purlee, as well, as he showed us how to use a lot of different tools.”

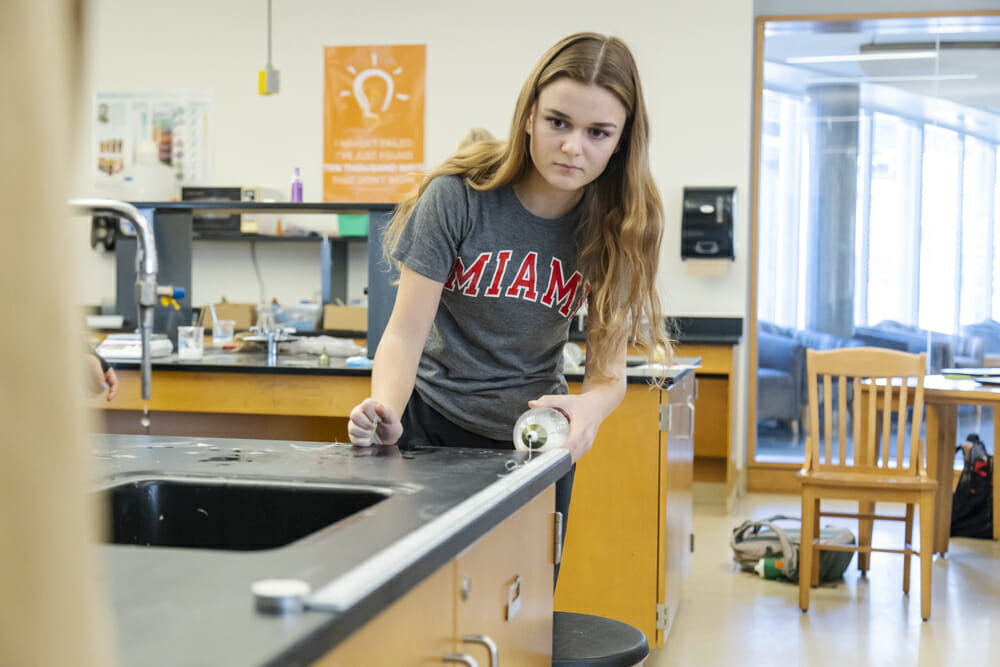

Part of this project led students to the Upper School Makerspace where students printed their final nozzle designs. “I also loved being able to come to class and test and work with my hands the whole time instead of just sitting at a desk doing work,” said Caroline Bryan ’25. “I liked the 3D printing aspect of the project because it gave us an opportunity to learn how to use a different kind of technology and to spend time in the makerspace during the project.” In late November, the fire extinguishers were officially tested during the Fire Extinguisher Competition, where students could see what their peers developed. “Testing the fire extinguisher was the best part of the lab,” Sondrol said. “From testing, I was able to learn from the results what was going right or wrong with the design and improve it. Working through the scientific process in this lab and having a positive outcome of the design working is exciting and motivating.”

Lastly, bringing the project together, students assembled the components needed for a patent application. After all, that’s a very exciting step after the creation of a new product!

Students really liked this hands-on lesson where they indeed used the new knowledge they were gaining in real-time. “Although the lab was challenging as we had to meet various requirements, it was cool to see our extinguisher, after many revisions, come together to make a final product,” said Ethan Waymire ’25. “It took a lot of work to engineer our final product, but my favorite part was when we put out the flame for the first time.”

Getting the desired result was no easy task. Jacob Daus ’25 said, “One thing that surprised me when creating our fire extinguisher was how small imperfections can mess up our end result. The project really taught us how to problem solve through multiple different designs so we could get a working prototype.” Bryan said, “I was surprised at how difficult it was to come up with a successful way to initiate the reaction within the given project restraints. We were not allowed to cut the bottle or shake it, and that ruled out a lot of my group’s initial ideas on how to get the reactants into the bottle and mix them. Eventually, we found a design that successfully put out the flame. Overall, the project was super fun.”

Thank you, Science 10 teachers Ethan Graf, Rachel Tourais, and Stephanie Matteson, for igniting so many learning lessons for students as they ultimately tried to put out their mini flames. Maybe one of them will come up with a more effective fire extinguisher one day!