Several years ago, the Science 10 team worked to build a curriculum that would strategically promote student collaboration and discourse, advance the use of driving questions, and scaffold a sequence of knowledge-in-use lessons. (Knowledge-in-use is the capacity that learners need to apply knowledge to make decisions and solve problems, and to evaluate when and how to get more information when necessary.)

Basically, our teachers want our students to go beyond memorizing facts and procedures, and, by exposing them to authentic experiences with open-ended questions/problems and unresolved solutions, they hope students will develop a deeper, more connected level of knowledge. These burgeoning young scientists leverage scientific and engineering practices for authentic purposes. Scientific ideas become tools they can harness for creating solutions, rather than simply means to meet assessment and assignment criteria.

How does this translate to the classroom? The team created a series of lessons and experiments that culminated in the design and creation of fire extinguishers, a curriculum that Interim JK-12 Science Chair Paul Zahller credits as being one of the most robust and innovative lessons in the school. For the students, this meant an interactive, engaging, and fun process that also promoted collaboration with their peers. “I learned a lot in this project such as how to work closely with other classmates and how to persevere and continue brainstorming when your initial idea fails,” said Bridget Clennan ’24. “This project was a lot of fun because we had so much freedom to try as many things as possible and had a lot of support from Ms. Anderson.”

We gave you a peek inside part of the process with our corkomodules story in September. This experiment was a great example of the type of work that led students through their unit, a scaffolded approach where knowledge and understanding build toward a final project. Through their work in this unit, students used a foundation of solution and gaseous stoichiometry, providing them with real-world application and engineering experience to deepen their understanding and strengthen their skills.

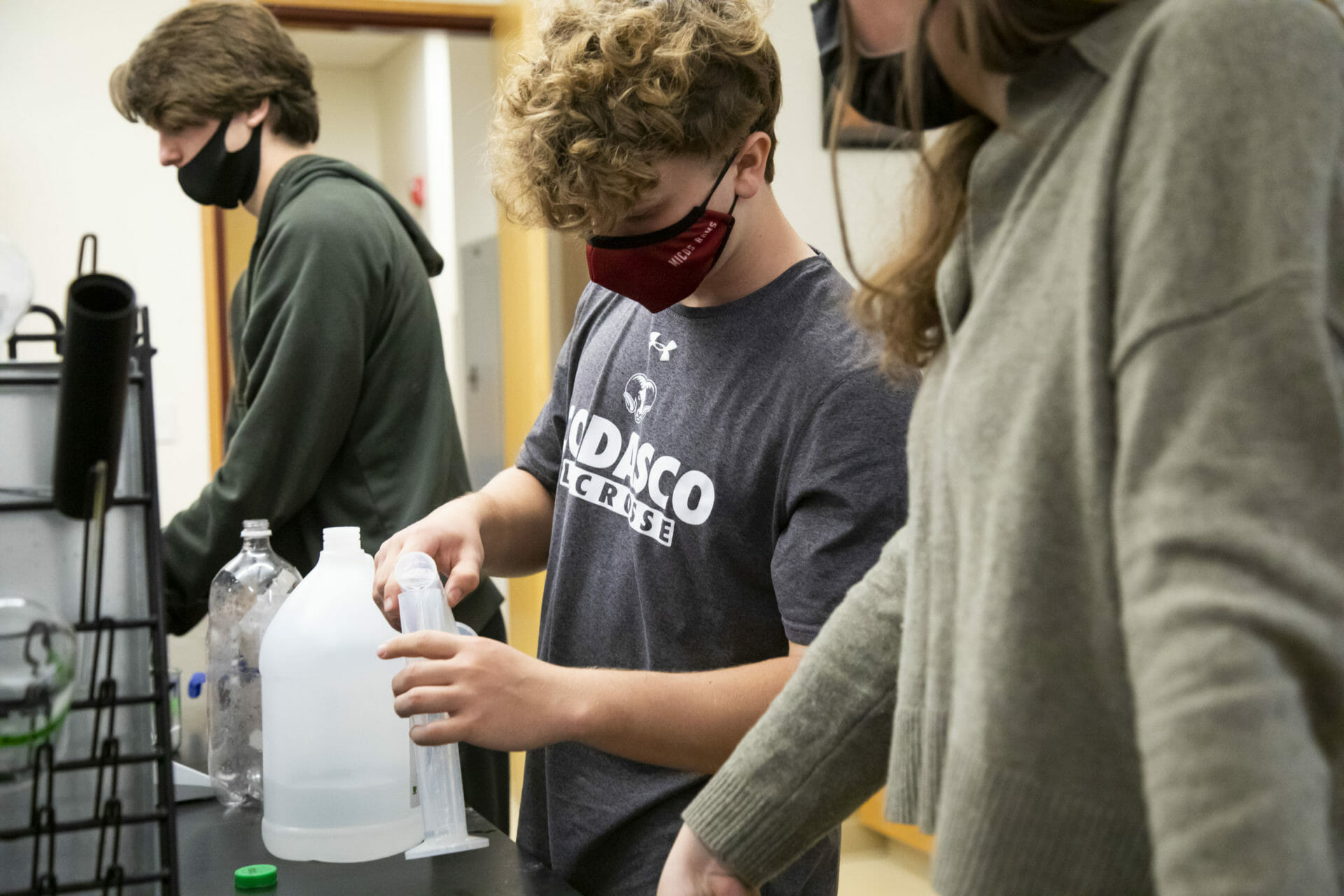

Student scientists were divided into teams of two-three students, who then applied for and were appointed to one of three roles on each team: chemical engineer lead (CEL), mechanical engineer lead (MEL), and quality manager lead (QL). They underwent formal Tinkercad software training so they were prepared to use the system to help create their designs. They used Google Sheets to log their ideas.

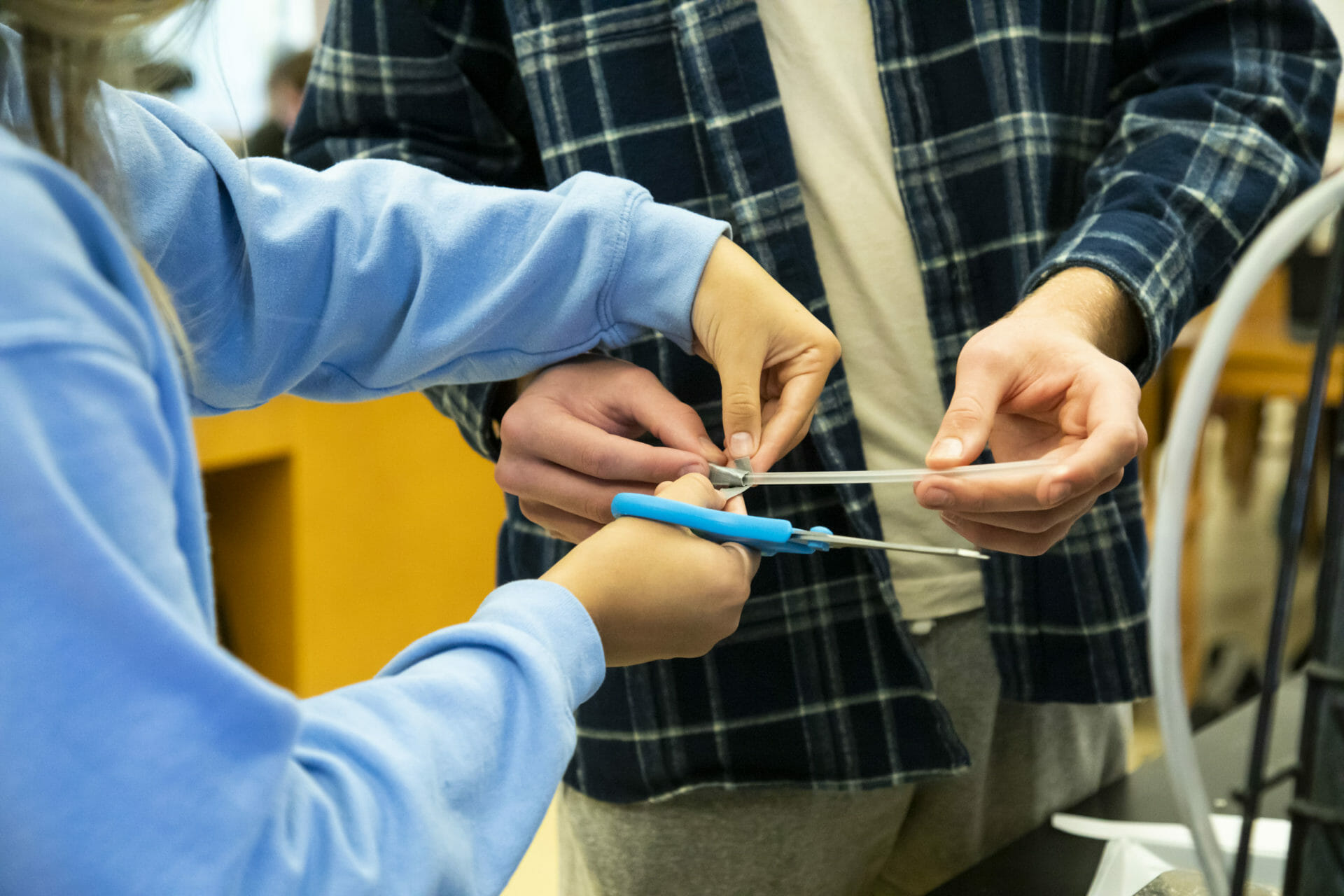

Members of each role broke into specialist groups during one class, sharing ideas and thoughts before reporting their findings back to their teams. These findings led to possible modification and redesign. They continued over several class periods, designing and testing, then redesigning and testing again with inexpensive materials.

Zoe Zlatic ’24 said, “I loved how we had plenty of time to experiment with different concepts and designs. It was also really fun working in the Maker Space, and I loved how we got to design and print one of the fire extinguisher components using 3D software.”

Each team worked under the same system constraints, which included:

- Required use of this equation: HC2H3O2 (aq) + NaHCO3 (s) → CO2 (g) + H2O (l) + NaC2H3O2 (aq) (A vinegar and baking soda creating CO2 pressure not to exceed 2.0 atm.)

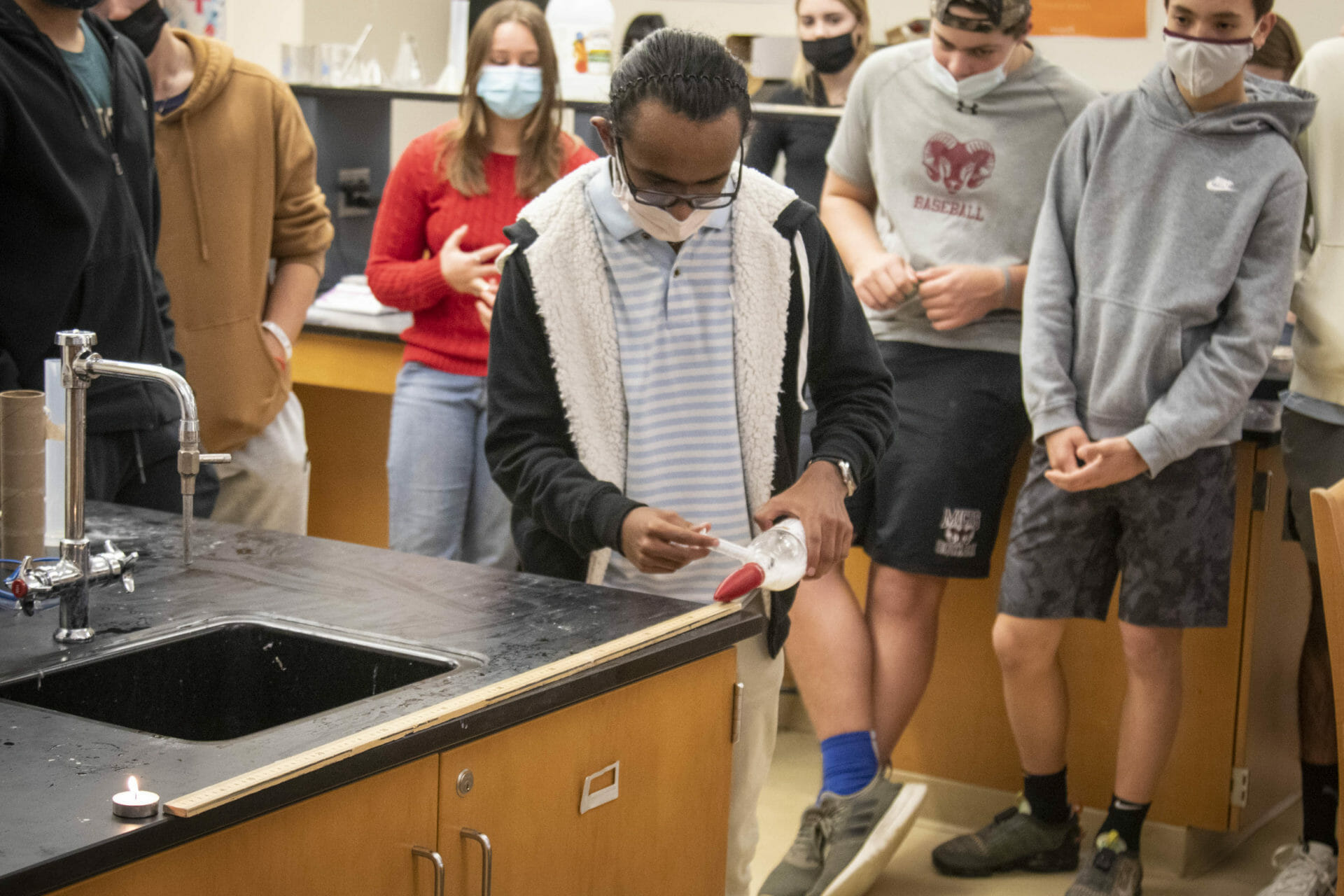

- Time limits of requiring no more than 15 seconds from when the initiation mechanism is started to extinguish the flame

- Distance limits that meant their extinguishers could be brought no closer than 1 meter from the flame. While the students could not move their extinguishers closer, they could sweep it back and forth. The nozzle of their extinguishers could not be more than 10 cm above the flame.

- Handling: Only one person can actually perform the demo.

- The pH of the remaining material after the reaction must be between 6-8.

- The flame was classified as a Class B fire.

- Room setting meant that there was no wind between the extinguisher and the flame, and that the ambient temperature was 60-80 degrees F.

- Mechanical constraints meant that the extinguisher could be handled by only one team member, and contain only one initiation mechanism. It must be able to be handled with hands only (which means an appropriate weight of no more than six pounds), and the extinguisher bottles could not be squeezed.

- The vessel themselves must be plastic, commercially fabricated bottles no greater than two liters in volume, and could not exceed a mass of five kilograms. Engineers had to create a method of initiation (mixing the chemical components) that did not involve shaking.

- Extinguishers had to be appropriately labeled with Class Type (B), and include pressure and chemical yield labels.

- All chemical substances had to be contained within the container.

- A 3D-printed nozzle must be used and connected to the vessel.

“It really surprised me how difficult it was to create a fire extinguisher that worked because I first thought creating a chemical reaction with enough pressure would be easy,” Clennan said. “My favorite part of this project was definitely working together in groups because it made it a lot more fun and everyone had something to contribute.” This is exactly what Science 10 Teacher Kelly Anderson hoped to accomplish. She said, “I hope that students learned the importance of collaboration through working on a team, learning skills such as communication, sharing/respecting ideas, and time management.”

Finally, it was time to head to the Makerspace to print their final nozzle designs. Each class hosted a Fire Extinguisher Competition, and students were able to see how their peers did. These were exciting days in the Science 10 labs! Zlatic especially enjoyed this part of the process. She said, “My favorite part of the project was the final competition where each group got to explain and test their design for everyone else; it was really cool to see what my classmates came up with.”

What follows the creation of a new product? A patent, of course! To round out the project, students assembled the components needed for a patent application, including appendices that supported their claims. This application and appendix were the basis of their grade for the project, not the fire extinguisher itself. Science 10 Teacher Kelly Anderson explained, “We intentionally did not grade their final product (their physical fire extinguisher) because we wanted them to feel comfortable to fully experience the design process/utilize their creativity without worrying about failure. I hope students learned the value of taking risks.”

She also wants her students to feel proud of what they were able to accomplish. “This was a very difficult challenge that not all were able to meet; the most important thing was NOT if they were 100% successful, but rather that they were able to produce something unique while learning the importance of failure, resilience, patience, creativity, and curiosity.”

Although Zlatic’s team did not extinguish the flame (along with most of the other groups), they learned a lot and had a great experience. She said, “I had a blast doing this project! I learned a ton, specifically how I can be a productive engineer and a good teammate at the same time.”

“I hope that this experience gets students excited about science (and learning),” said Anderson. “I hope that this project gave them the opportunity to be proud of something they created and to help them never stop wondering.”